Starting from blanks or working from coil, TAIGONG offers different solutions for Cable Tray Roll Forming Machine manufacturing.

The lines we propose allow industrializing any type of cable tray. Our Automatic Roll Forming Machine lines are suitable to manufacture cable trays, in different widths and heights, by just changing the coil and roll forming width.

The whole Cable Tray Making Machine line is electronically controlled, in order to ensure the right feeding, punching and cutting is achieved.

The Cable Tray Punching Machine lines are tested in our factory at real speed before delivery.

1. Profile Drawing and Products

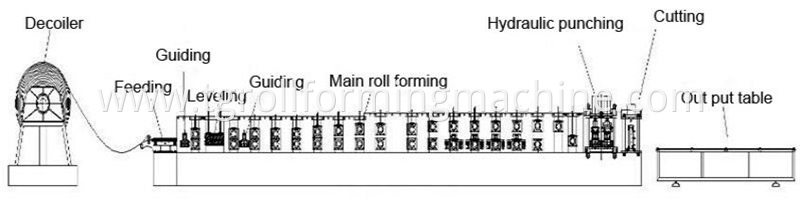

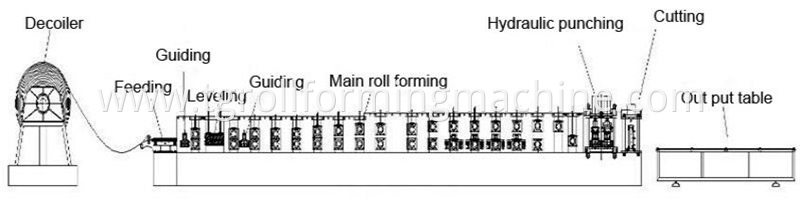

2. The Chart of Process Flow

De-coiler--- Leveling--- Hydraulic Punching--- Roll forming--- Hydraulic Cutting- Output Table

3. The equipment including

| Automatic changing sizes roll forming machine | 1 set |

| Electrical control system | 1 set |

| Hydraulic system | 1 set |

| Manual de-coiler | 1 set |

| Leveling machine | 1 set |

| Servo feeding machine | 1 set |

| Press machine | 1 set |

| Cutting device | 1 set |

4. Technical specification and details

| Material | Galvanzied steel coil; Stainless steel coil; Aluminium sheet coil |

| Cable tray type | Trough type, ladder type, trays type |

| Cable tray width | 100-600mm |

| Cable tray height | 50-200mm |

| Thickness | 0.6-2.0mm (for GI sheet and coil) |

| Feeding width | 200-1050mm |

| Strength | Q235Mpa |

| Speed | 0-10m/min |

| Size tolerance | 1mm |

| Size changing way | full automatic |

| Power | 4*4kw+7.5kw+9kw |

| Roller material | #45 forged steel with hard chrome treatment |

| Cutter blade material | Cr12 with quenching treatment |

| Dimension | 20000*2500*1500mm (L*W*H) |

| Total weight | about 30tons |

Cable Tray C Roll Forming Machine Forming Style:

Cassette structure,

Suitable Material Thickness: As per required

Suitable Material: Steel

Suitable Material width: <500m ( Not affected by material thickness )

Product specifications: as per customer required ( final profile drawing)

Shaft diameter: 55mm

Forming stations: about 30 Rows

Roller material: Gcr15 air-hardening hardness of HCR58-62

Shaft material: 45# steel precision machined conditioning treatmennt

Cassette arch model: GY180 Enhanced

Servo motor power : 11KW ( Frequency, with brake )

Speed: 8--15m/min

Decoiler :

Manual Type

Inner diameter:φ470-550mm

Outer diameter:φ1400mm

Cutting :

Hydraulic cutter

Hydraulic pump station: 4.5kw

Number of knives: one set. Material (Cr12Mov) steel

Output Table:

Steel Material

1 set

Electrical Control System :

The entire line with PLC control, liquid crystal display touch screen, man-machine interface

Brand: Delta from Taiwan, also can be used the brand as per customer requirment.

Punching Device:

Nominal force : 1600KN

Slider travel : 130mm

Number of slider strokes: 40times/min

Motor : 4.5 Kw

Rotating speed: 970 turn/min

5. Machine Overview

6. Scene application

7. Customer

8. Loading

9. Payment terms and after-sale service

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping Perforated Cable Tray Roll Forming Machine

3) Delivery time: 45-50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training:

1. If buyers visit our factory and check the Cable Tray Machine, we will teach you how to install and us the Cable Tray Roll Forming Making Machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual or video to teach you to install and operate Cable Tray Roll Making Forming Machine

The buyer should pay the installation charges (USD 100 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Our main products include Stud Track Roll Forming Machines, Steel Frame Forming Machines, Purlin Roll Forming Machines, Welded Pipe Making Machines, Highway Guardrail Roll Forming Machines, Metal Expanded Mesh Production Lines and so on. If you have any further question of our Cold Roll Forming Machine, please feel free to contact me. Product Categories : Cable Tray Forming Machine > Cable Tray Roll Forming Machine