Our company can supply complete production lines and Rack Roll Forming Machine according to your requirement. We supply many different sizes of Tunnel Rack Roll Forming Machine with our auxiliary equipment. We have gained a good evaluation from users because of advanced technology, perfect quality and after-sale service. The Utility Tunnel Rack Machine is used to making rackets which to hold electric wires, oil, water etc. Utility Tunnel Rack Roll Forming Machine production line speed about 8--15m/min, adopts non-stop hydraulic cutting system, machine fully automatic with PLC control system.

We can also produce Solar PV Rack Roll Forming Machine and Solar Tail Box Rack Roll Forming Machine according to customers' requirements.

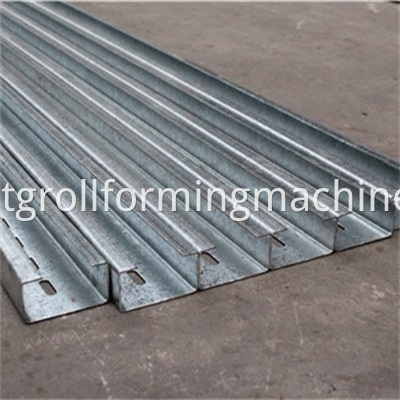

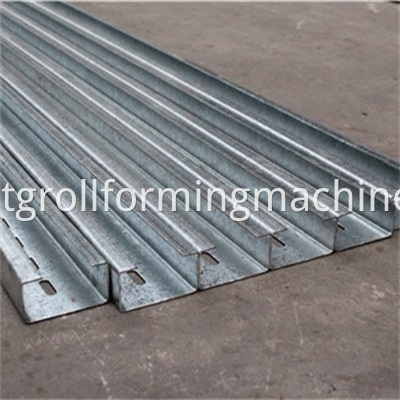

1. Profile Drawing and Products for Reference

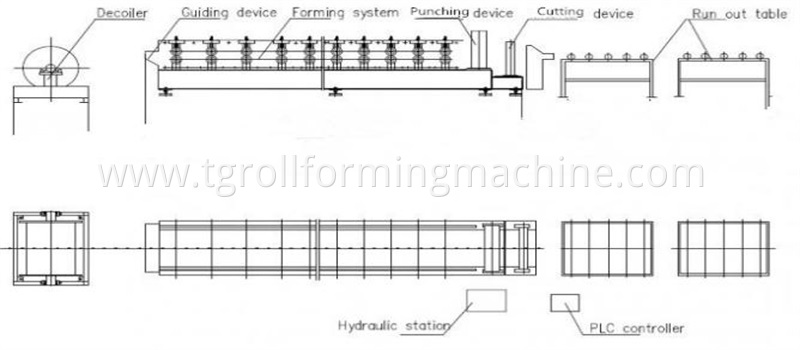

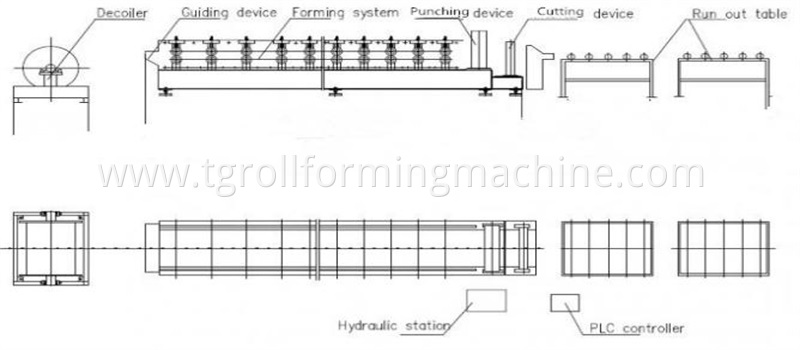

2. The Chart of Process flow

3. The equipment including

| Pallet Rack Roll Forming Machine | 1 set |

| Electrical control system | 1 set |

| Hydraulic system | 1 set |

| Manual de-coiler | 1 set |

| Leveling machine | 1 set |

| Servo feeding machine | 1 set |

| Press machine | 1 set |

| Cutting device | 1 set

|

4. Machine Details:

| Name | Introduction |

| Automatic Decoiler | Inner diameter:460~510mm Outer diameter:1200mm Max.Capacity: 5T; Manual power expands the coil inner surface; Raw material: Galvanized sheet, Material thickness: 2---4 mm, Color: Blue (or base on customer request) Dimensions:1700mm*1000mm*800mm |

| Punching Device | Nominal force : 1600KN, Slider travel : 130mm, Number of slider strokes: 40times/min, Motor : 15Kw, Rotating speed: 970 turn/min, Dimensions : 2045*1655*2870mm, |

| Forming Machine | Cassette structure Forming stations: 14 Rows, Roller material: Gcr15 air-hardening hardness of HCR58-62 , Shaft material: 45# steel precision machined conditioning treatmennt, Shaft diameter: ¢75, Main Engine power: 22 KW with cycloidal reducer Voltage :380 v 3 phase, Capacity: 8-15m/min, Transmission type: Chain driving, Dimension: *1500*1400mm, |

| Cutting Device | Cutting: hydraulic cutting; quenching HRC58-62 Cutting style: automatic style Cutting die material: Cr12 Mov. |

| PLC control system | Brand optional: Panasonic, Mitsubishi,Siemens,Delta Frequency Control system with touch screen, Dimension: 700*700*1000mm, User interface, button labels and literacy should be in English or as per required, Control the start and the stop of whole machine, |

| Pump station | From Shanghai Tuojiang It supplies the power for the hydraulic cutter. All hydraulic accessories are all use Chinese famous brand products. Hydraulic motor power: 4.5KW |

| Output table | Weldedpipes, passive |

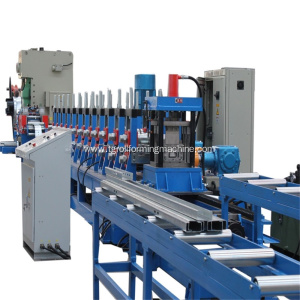

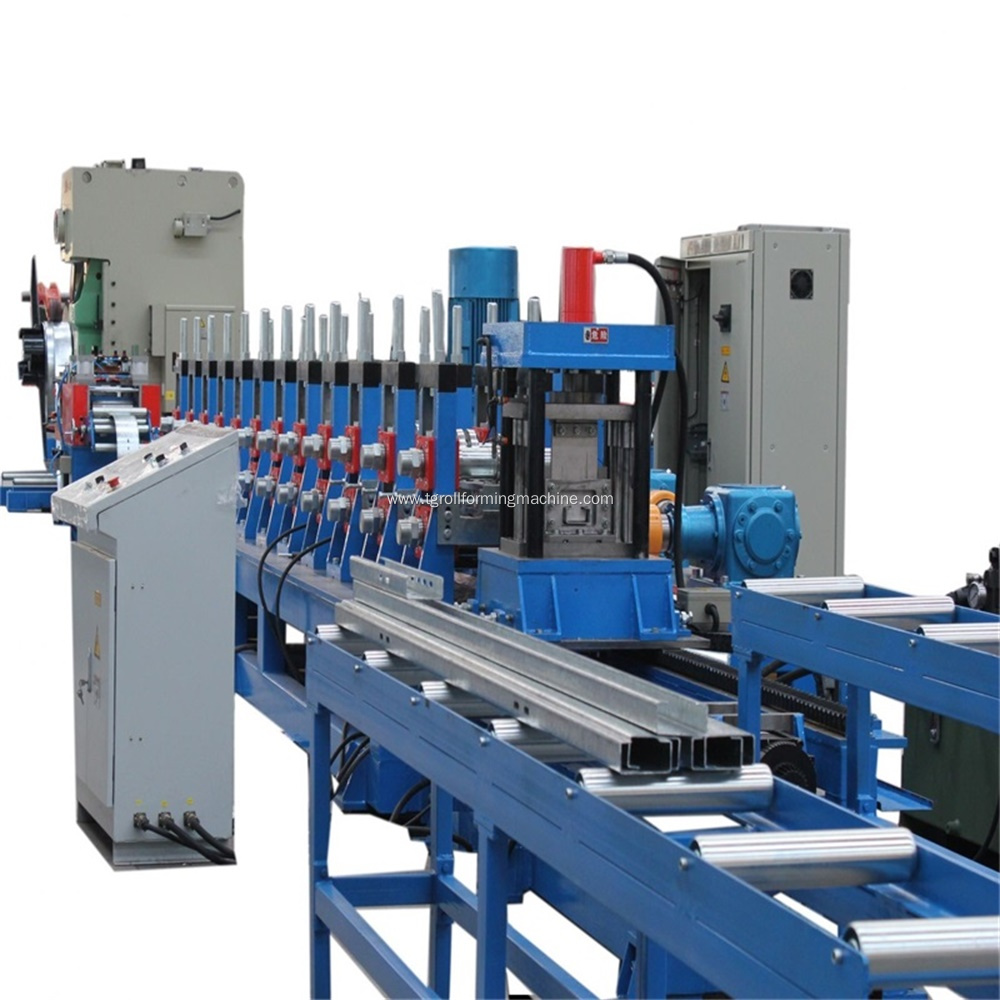

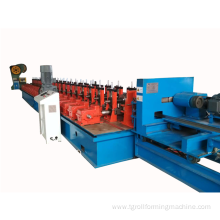

5. Machine Overview

6. Scene application

7. Customer

8. Loading

9. Our Services

1. Warranty :One year,and we will provide technical support for whole life of the Cold Bending Equipment

2. Delivery time: Within 30 days after deposit receipt your payment

3. Guarantee period: 1 year free service/ pay service all the machine life

4. Installation and training If buyers visit our factory and check the Seismic Support Roll Forming Machine

we will teach you how to install and use the Cold Bending Equipment for Pipe Rack and also train your workers/technician face to face.

Without visiting,we will send you user manual and video to teach you to install and operate.

If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things.

10. Payment terms and after-sale service:

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping.

3) Delivery time: 50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc

6) Installation and training:

1. If buyers visit our factory and check the Roll Forming Machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual to teach you to install and operate.

3. COST OF INSTALLATION:

The buyer should pay the installation charges ( USD 80 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc

Our main products include Stud Track Roll Forming Machines, Steel Frame Forming Machines, Purlin Roll Forming Machines, Welded Pipe Making Machines, Highway Guardrail Roll Forming Machines, Metal Expanded Mesh Production Lines and so on. If you have any further question of our Cold Roll Forming Machine, please feel free to contact me.

Product Categories : Rack Roll Forming Machine > Utility Tunnel Rack Roll Forming Machine